Press

Inter Holdings, a company specialized in ultra-high vacuum technologies, performs an experimental study to promote a green transformation in the Sake industry.

Contents

Inter holdings Inc. ( HQ: Shibuya-ku, Tokyo, Representative/CEO: Ikumi Narui, https://www.inter-hs.com/) starts its experimental study with 5 participating breweries on 10 November 2023 to promote green transformation through vacuum Sake. Inter Holdings Inc. provides solutions to supply chains through patented vacuum technologies enabling as high as 99.5% vacuum.

Overview

The company perform this experiment to clarify the underlying problems on the brewery side and the supply chains then seek for potential solutions.

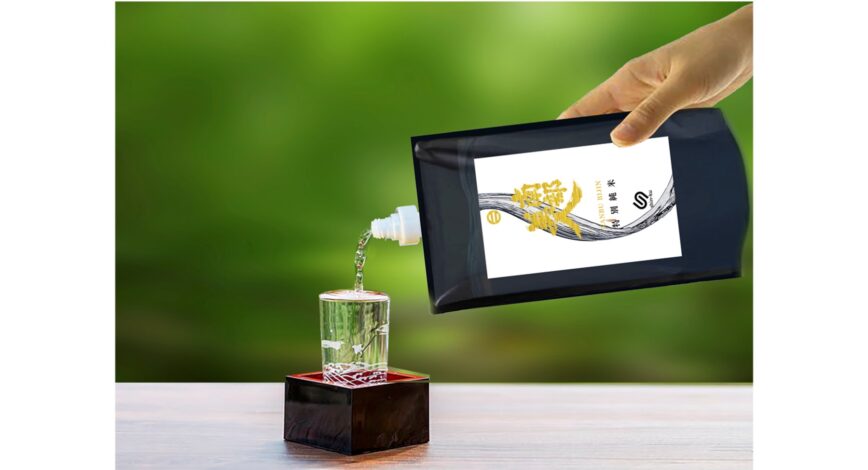

Consumers are provided with opportunities to enjoy Sake sip by sip every day, with the unique technologies of vacuum valves that maintains the content fresh. The experiment will examine the merits of replacing 1.8L bottles with different containers, as well as potentially reduced costs and Co2 emissions brought by this replacement.

The company plans to develop vacuum system exclusive for Sake breweries which can help promote overseas sales. It aims to gain 100 brewery participants, equivalent of about 10% of the total 1400 breweries of domestic breweries.

Inter Holdings assists clients to provide solutions for the issues such as food waste, greenhouse gas (Co2) and costs occurring in the supply chains, through its unique vacuuming technologies.

Commentaries from the participating breweries

- Zaku (作) vacuum version / Mie Prefecture

The brewery decided to produce vacuum-pouched Sake to widely introduce its symbolically fresh Sake. It is the first trial since the start of Shimizu Seizaburo Shoten Ltd in 1869, approximately 150 years ago. I hope more clients have a chance to try our Sake in this way.

(Representative director Shinichiro Shimizu, Shimizu Seizaburo SHoten Ltd.)

- NambuBijin Tokubetsu Junmai (南部美人 特別純米) vacuum version / Iwate Prefecture

Thanks to the technologies of Inter Holdings, I believe that the project has a potential to provide more opportunities for those who are not familiar with Sake to drink it for the first time, while controlling the quality and environmental impact.

(Kosuke Kuji, Representative director and President of NambuBijin)

- Mizubasho Junmai Daiginjo SUI (水芭蕉 純米大吟醸 翠) vacuum version / Gunma Prefecture

The brewery decided to join the project, inspired by a variety and possibility in Sake containers. We would like to take this chance to reconsider the environmental impact and resources.

(Noriyoshi Nagai, Representative director of Nagai Sake Inc.)

- Junmai Daiginjo Shinkura KAGURA non-filtered, non-water-added vacuum version / Kyoto-fu

This project on vacuum pouch can solve a majority of problems caused by bottle containers, i.e. weight, fragility, and oxidation of the remaining content.

As a 300 year old brewery, we see the opportunity extremely valuable to participate in this type of innovative project. Let us all enjoy Sake and its interaction with new technologies.

(Jiemon Matsui, Representative director of Matsui Sake Brewery)

- Shichida Junmai Ginjo (七田 純米吟醸) vacuum version / Saga Prefecture

Maintaining the vacuum condition of the container is unarguably a merit to deliver fresh Sake to customers. However, we see larger potentials in the weight of the container.

By reducing the container weight, it helps to reduce the Co2 emissions during the delivery. The brewery has a high expectation on the project as a Green Transformation Modelling Company of the Saga Prefecture.

(Kensuke Shichida, 6th Generation master of Tenzan Sake Brewery Co., Ltd. )

Vacuum Sake Project to support a challenge in Green Transformation in Sake industry

Sake is one of the symbolic items in Japanese culture, however its domestic consumption has been declining in the recent years. What is worse, covid pandemic had a negative effect in the consumption of Sake. Demands for 1.8L bottles were in a decrease, which resulted in a business closure of bottle producers and bottle recycling bodies. Delivery fees rose due to an increased needs for the delivery of other items. Sake industry is facing a number of problems.

Having seen an increasing demand of Sake at overseas restaurants, the project was launched in collaboration with Sake expert Maaya Takaoka, to challenge these problems with green transformation through vacuum technologies.

Ultra-high vacuum technologies by Inter Holdings

Tadashi Hagiwara, a representative innovator in Japan, and the honorary chairman of Inter Holdings spent 30 years to develop it at Hagy Technology. Dr. Hagiwara gained more than 600 patents and had an experience of being engaged in the Apollo space projects. Dr. Hagiwara received a hint of advanced vacuuming patent technologies from the fueling parts of rockets. Inter Holdings received a patent of this technology which achieves vacuuming ratio of 99.5% which is only available with this technology, and started developing and selling vacuum containers. For example, it is possible to maintain the flavour of new-rice* fresh even 6 months after the polishing. ‘Rice is equally delicious 3 month after the polishing’, says a farmer. Olive oil can also be stored free from oxidation for 10 months. Tastes are the witness of the vacuum technologies.

* new rice means the first rice of the season, like Beaujolais nouveau for wine

Company profile

Name : Inter Holdings Inc.

URL :https://www.inter-hs.com/

Address: 3-42-13, 1F, Ebizu Shibuya-ku, Tokyo

Representative : CEO, Representative director, and President, Ms. Ikumi Narui

Founded in : March 2019

Capital : 51 million yen

Company slogan: Committed to non-disposal life every day, and continue it to the future

Business: License of vacuum technologies and product sales, and Green transformation consulting

https://prtimes.jp/main/html/rd/p/000000017.000058890.html